Once Flowing in the Bottom Wiring

The SWA cable enters the Zappi enclosure by way of an out of doors water resistant gland. I bought 5 metres of 6mm² SWA cable to run from my consumer unit to my desired charger location. On researching the topic further I found an open source charger (the EVSE) with good documentation. Logically, car manufacturers must have to make sure their onboard SMPS chargers have good energy issue else the additional currents would trigger issues in domestic setups, I agree. If there is a fault and some current does not return then it should be going to earth. After wasting per week or two on this and playing round with some very sketchy Windows software for modifying UEFI payloads, I gave up going this route. I wrote the Arduino software for it and all design information, software and part lists are available on the GitHub page. Do you may have a hyperlink to the software? The reply is: So when one fails, we don't have to replace both. That's like operating two 40 Watt followers for one hour, it is not insignificant and it does not even account for battery charging losses. Yet, within the summer time, I had loads of energy obtainable and had no problems charging my iPad and other devices.

The SWA cable enters the Zappi enclosure by way of an out of doors water resistant gland. I bought 5 metres of 6mm² SWA cable to run from my consumer unit to my desired charger location. On researching the topic further I found an open source charger (the EVSE) with good documentation. Logically, car manufacturers must have to make sure their onboard SMPS chargers have good energy issue else the additional currents would trigger issues in domestic setups, I agree. If there is a fault and some current does not return then it should be going to earth. After wasting per week or two on this and playing round with some very sketchy Windows software for modifying UEFI payloads, I gave up going this route. I wrote the Arduino software for it and all design information, software and part lists are available on the GitHub page. Do you may have a hyperlink to the software? The reply is: So when one fails, we don't have to replace both. That's like operating two 40 Watt followers for one hour, it is not insignificant and it does not even account for battery charging losses. Yet, within the summer time, I had loads of energy obtainable and had no problems charging my iPad and other devices.

Nice. I like that though it undoubtably adds complexity and you’ve acquired ask the query whether a 1W saving whilst charging is worth the added effort… I like the wikipedia article on electrical damage. A current transformer doesn’t wish to be open circuited. I like the idea about thermal safety too. To reinforce the remark about safety done in Arduino, that’s the major point where I would suggest you revise your design, or discourage someone from reusing this design. Now, nonetheless, the interior design of Unit 2 is such that the bottom current flowing through FG additionally flows by means of G-G' before it encounters the ground wire going to level D. G-G' is nearly certain to be a PCB observe with higher resistance than any of the cabling, and so the voltage drop across it can be comparatively massive, and the hum efficiency correspondingly poor. While normally a USB port wouldn't hold up properly on a versatile PCB, this one is going to house a USB device that's semi-permanently installed, low voltage power cable so it won't undergo the stress of fixed removing and insertion. The TinyPilot Power Connector permits the Pi to receive three Amps of energy by way of its USB-C port without losing USB OTG performance.

Nice. I like that though it undoubtably adds complexity and you’ve acquired ask the query whether a 1W saving whilst charging is worth the added effort… I like the wikipedia article on electrical damage. A current transformer doesn’t wish to be open circuited. I like the idea about thermal safety too. To reinforce the remark about safety done in Arduino, that’s the major point where I would suggest you revise your design, or discourage someone from reusing this design. Now, nonetheless, the interior design of Unit 2 is such that the bottom current flowing through FG additionally flows by means of G-G' before it encounters the ground wire going to level D. G-G' is nearly certain to be a PCB observe with higher resistance than any of the cabling, and so the voltage drop across it can be comparatively massive, and the hum efficiency correspondingly poor. While normally a USB port wouldn't hold up properly on a versatile PCB, this one is going to house a USB device that's semi-permanently installed, low voltage power cable so it won't undergo the stress of fixed removing and insertion. The TinyPilot Power Connector permits the Pi to receive three Amps of energy by way of its USB-C port without losing USB OTG performance.

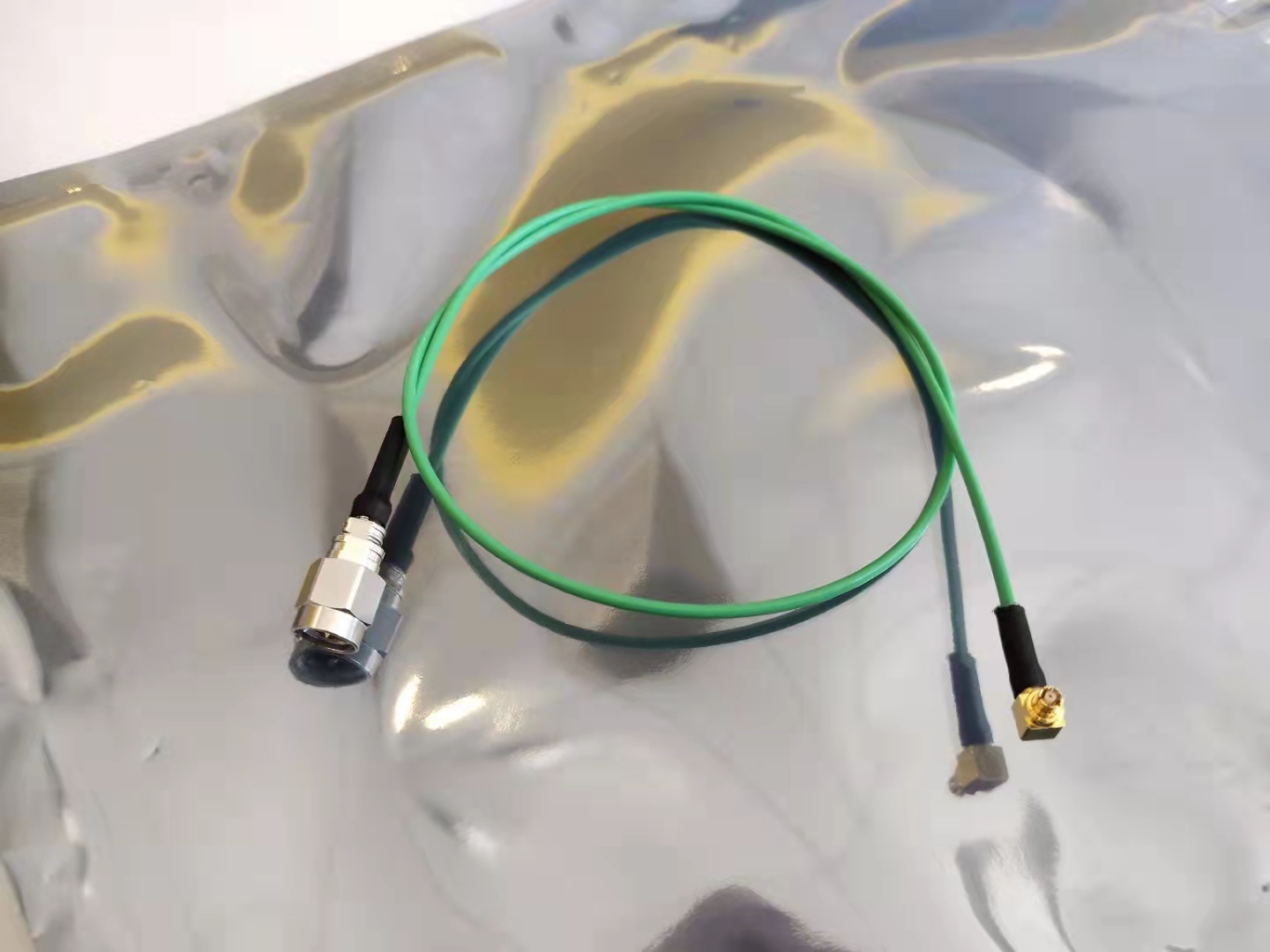

Based on the datasheet the dropout at 20 mA load is about 1.6 V at 0℃ which allows us to up our op-amp rails to about 13.Four V if vital. Therefore R3 & R17 present a small load for them. There were no port errors, it was simply by no means detected as if it weren't powered up. There are limits to how far you may take this- while a simple balanced enter will give 40dB of rejection at low cost, increasing the cross-sectional area of copper in the ground of an audio cable by a factor of one hundred occasions will not be going to be either straightforward or low-cost. I've learnt about earthing techniques, PEN faults, RCDs, cable present capacities and so on. I think I have educated myself sufficient to have constructed an adequately protected system. If now we have a 20mA present on the primary and a 1:400 turns ratio we’ll have a 50uA secondary current. We put 1 turn on the transformer main by passing the reside and impartial once by way of the ferrite core. A present transformer is analogous to a voltage transformer. HUM INJECTION BY TRANSFORMER STRAY FIELDS. The first port accepts USB power, so you'll be able to nonetheless deliver a full 3 Amps to the Pi.

So 210 Watt of solar (receiving mostly oblique sunlight) nonetheless couldn't power my Raspberry Pi by the winter under my circumstances. It can't be the firmware on the flash chip itself because that could be toast and it will nonetheless self-heal. After poking across the motherboard, I located the firmware flash chip proper subsequent to the M.2 slot below a plastic sheet, and it is a Winbond W25R256JV 32 Megabyte 8mm x 6mm chip. Another 32MB flash chip? What is doing the flash verification? So my (eventual) idea was to create a brand new flex PCB that goes instead of the fingerprint reader and has an FFC 8-pin connector for the motherboard cable, then routes the four USB pins right down to a USB port next to the show connector. Apparently the fingerprint reader is designed to only need 3.3V for its USB connection (presumably taking energy from close by i2c components which use 3.3V), and many of the USB gadgets that I tried worked with only 3.3V as nicely. We probably didn’t need the low-offset options of the OP07. Connect the USB cable to your Pi’s USB OTG port. This ensures that voltage variations between the computer’s energy supply and the Pi’s energy source won’t trigger undesirable energy backflows.